CNC Machining

CNC Machining is different than other machining processes that rely on manual machine operation or handcrafting. CNC (Computer Numeric Control) is fully-automated, using computer software in conjuction with advanced machining equipment to produce the ultimate in precisely manufactured parts.

CNC technology can be used with a variety of materials and in conjunction with other cutter and milling machines. Using computers and software programs to control manufacturing equipment, CNC machinists can make more precise cuts and create more intricate designs compared to manual machining or working by hand. Our Ickler team of CNC experts and skilled craftsmen are able to help you with any precision machine parts you might need.

For an in-depth look at CNC Machining, click here for an article by Ickler CEO Todd McGonagle

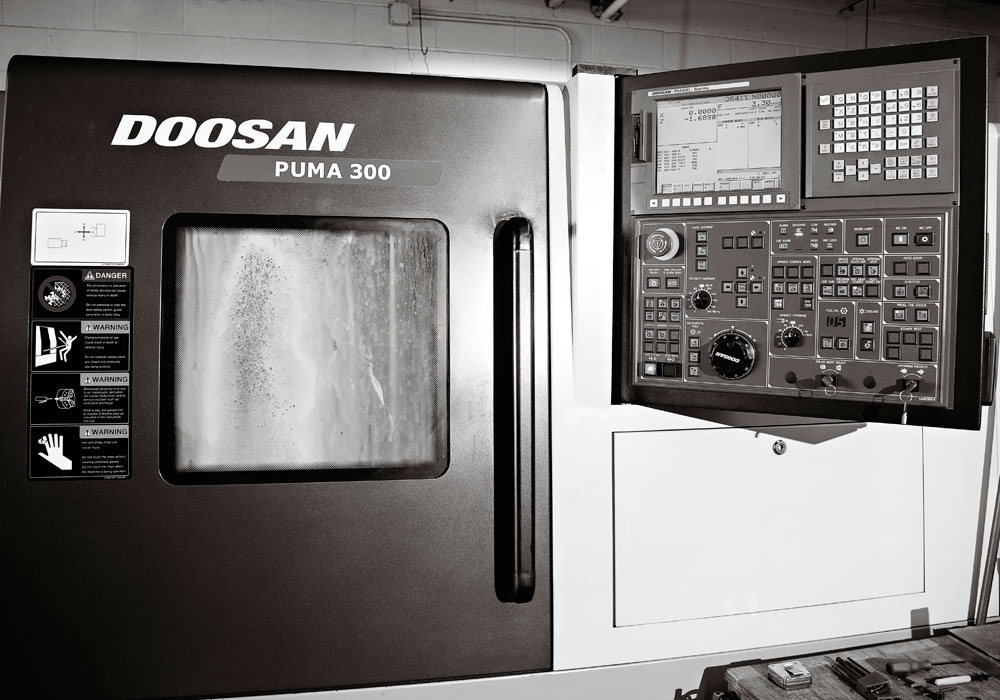

Ickler CNC Capabilities

Milling Capabilities

- 4 axis milling

- Table travel 20" to 40"

- Prototyping

- Live tooling

Turning Capabilities

- Full live tooling

- Up to 4" bar feeding

- High speed 6" chuck w/20hp motor

- Up to 12' chuck w/30hp motor

- Prototyping

Our Services Include

- CNC turning centers with bar feeder for complete run pricing

- CNC mills for simultaneous production and custom work projects

- Large manual machine department for single run projects, custom work and replacement part duplication

- CNC Engraving

- CNC Engineering

- Plasma CNC Cutting and Engraving

- Design capabilities using latest software, including Solid Works and Surfcam

- Simple and easy conversion of CAD files

- A well-stocked metal rack minimizes your wait for materials

- We work with stainless, brass, aluminum, copper, cold roll steel, delrin, nylon, tool steel, and more.